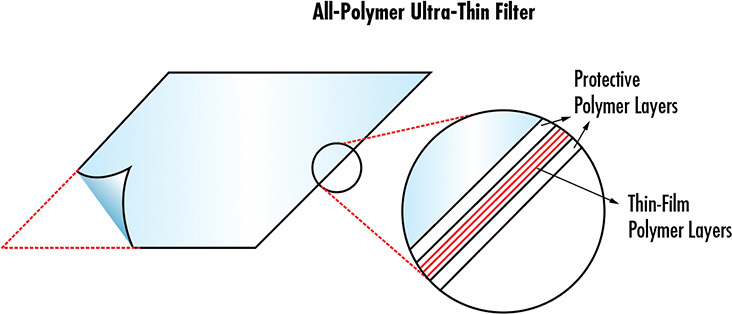

Ultra-Thin Longpass and Shortpass Filters are designed and constructed out of ultra-thin, flexible polymers and dyes. These filters are scratch insensitive and as durable as most industry hard oxide coatings. Comprised of hundreds to thousands of polymeric and dyed sub-layers, these filters can achieve high wavelength selectivity across the visible and near-infrared spectrum. Due to the low cost, low weight, and thin and flexible nature, these filters are perfect for high volume consumable applications such as vision and electronics or point of care devices for small and compact diagnostics equipment.

✔ Flexible Material Design

✔ 350nm to 1600nm Spectral Range

✔ Notch, Edge, Longpass, Shortpass, and Bandpass Filter Design Capabilities

✔ Multi-Notch and Multi-Bandpass Filters Available

✔ Scratch Insensitive

✔ OD 2 Absolute Design, OD 4 Blocking Achievable

✔ >90% Achievable Transmission

✔ Ultra-thin Design (200-500µm Thickness)

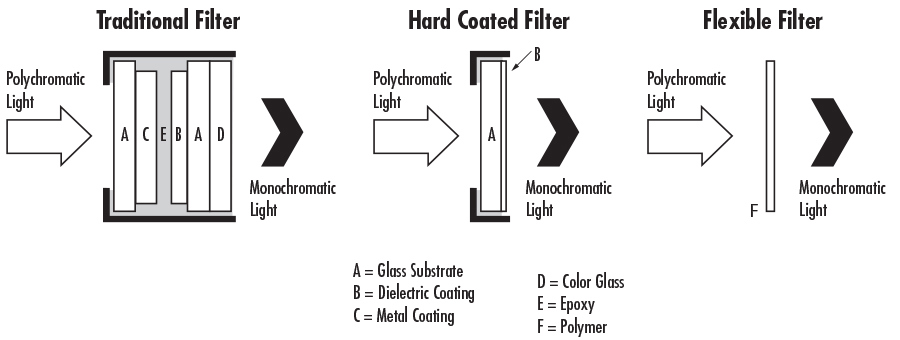

| Traditional Filter | Hard Coated Filter | Ultra-Thin Filters | |

|---|---|---|---|

| Substrate: | Stack of Glass, Metal, Plastic | Single Piece of Glass | Stack of Ultra-Thin Polymers |

| Transmission (VIS only): | 75% (approx.) | >90% | >90% |

| Clear Aperture: | >80% | >80% | >90% |

| Thickness: | 5mm | >1mm | 200 - 500µm |

| Blocking, Optical Density: | >OD 4 average | >OD 6 absolute | >OD 4 average |

| Temperature Stability: | Medium | High | Medium |

| Cut-on Steepness: | >3% | <1% | 2% |

| Cut-on Tolerance: | >3% | <1% | 2% |

| Price: | $$ | $$$ | $ |

What are Ultra-Thin Filters?

What are Ultra-Thin Filters?

How are Ultra-Thin Filters manufactured?

How are Ultra-Thin Filters manufactured?

What are the advantages of Ultra-Thin Filters?

What are the advantages of Ultra-Thin Filters?

Are there any disadvantages of Ultra-Thin Filters?

Are there any disadvantages of Ultra-Thin Filters?

What is the easiest way to customize the size of a Ultra-Thin Filters?

What is the easiest way to customize the size of a Ultra-Thin Filters?

How should I clean a Ultra-Thin Filters?

How should I clean a Ultra-Thin Filters?

How can I mount Ultra-Thin Filters?

How can I mount Ultra-Thin Filters?

Are these filters available in OEM quantities?

Are these filters available in OEM quantities?

What wavelengths are available?

What wavelengths are available?

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act