Edmund Optics® designs and deposits coatings with a high laser damage threshold (LDT) through advanced process control and monitoring of manufacturing parameters, including cleanliness and coating repeatability.

Our engineers design and fabricate custom laser optics including mirrors, crystals, lenses, filters, polarizers, prisms, beamsplitters, beam expanders, aspheric lenses, focusing objectives, and more in both prototype and volume production quantities.

Edmund Optics® has over 30 years’ experience producing high LDT optics. An in-house laser testing lab allows for internal process improvement and verification of laser damage threshold. Ultraviolet, visible, infrared, and ultrafast laser sources are employed to test optics in a wide range of use cases.

Edmund Optics® uses a wide variety of state-of-the-art metrology technologies to ensure that all specifications are met. Our in-process metrology capabilities include cavity ring-down spectroscopy, white light interferometry, non-contact 3D profilometry, and much more. An in-house laser testing lab allows for internal process improvement and verification of laser damage threshold.

Learn More

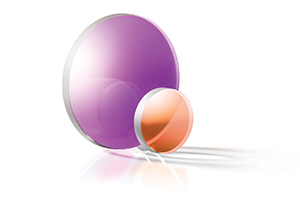

Laser Mirrors

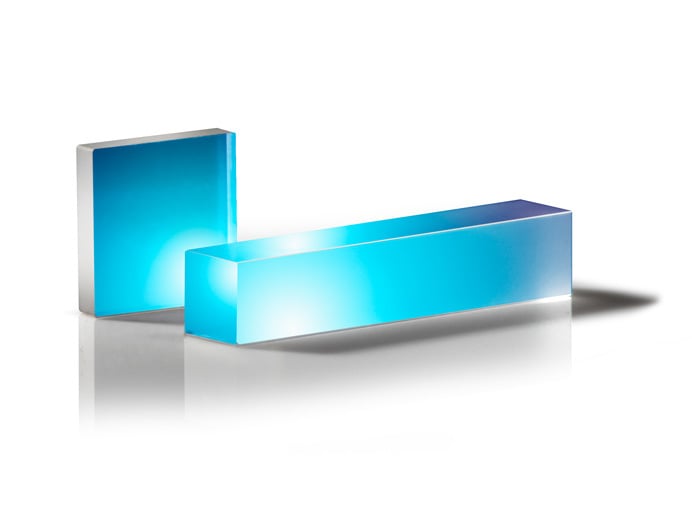

Laser Mirrors Laser Windows

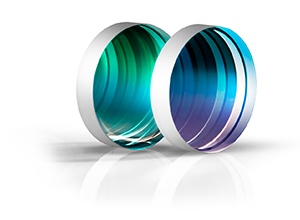

Laser Windows Laser Lenses

Laser Lenses Laser Crystals

Laser Crystals Laser Beam Expanders

Laser Beam Expanders Reflective Objectives

Reflective Objectives Laser Filters

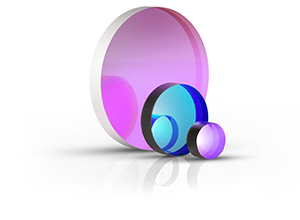

Laser Filters Laser Beamsplitters

Laser Beamsplitters  Laser Prisms

Laser Prisms  Laser Polarizers

Laser PolarizersGlobal Locations, Dedicated Laser Optics Center

34,000 sq. ft (3,159 m2) dedicated to manufacturing high laser damage coatings, laser crystals, and other high-precision laser optics. 30+ years regional presence through acquisition of Quality Thin Films (QTF)

Core Capabilities

21,225 sq. ft (1,972 m2) facility for advanced, high-volume laser assembly, laser optics design, and laser assembly metrology

Core Capabilities

120,000 sq. ft (11,150 m2); 20,000 sq. ft (1,860 m2) of dedicated manufacturing space. High-precision fabrication, coating, assembly, and testing cells

Core Capabilities

77,000 sq. ft (7,150 m2) of manufacturing space. Highly vertically-integrated facility for volume production of components such as laser-grade aspheric lenses

Core Capabilities

80,000 sq. ft (7,430 m2) of manufacturing space. High-precision spherical lenses, prisms, and other coated optics with over 50 years of experience

Core Capabilities