| Volume Pricing | |

|---|---|

| Qty 1-10 | €765,00 each |

| Qty 11-25 | €693,00 each |

| Qty 26-49 | €651,00 each |

| Need More? | Request Quote |

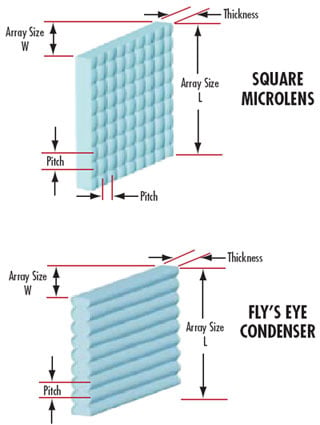

Microlens arrays are useful for homogenizing a variety of modern light emitters from line-narrowed excimer lasers to high power LEDs. Microlenses are well suited for applications that require high efficiency and non-gaussian uniformity. All microlens arrays are constructed from UV-grade fused silica, offering exceptional performance from 200nm to 2.5μm. The microlens arrays are manufactured using standard semiconductor technologies, yielding very accurate shaping of the lens profile and precise positioning of the lenses within an array. We offer our arrays in two configurations:

Our square arrays are available in a standard 10mm x 10mm configuration in a variety of lens pitch and focal length options. Square microlenses are commonly used for beam homogenization and shaping, yielding spot patterns or a square flat-top pattern. The lenses feature a high fill factor which eliminates zero-order hot spots in the illuminated field. Square lenses are often used in pairs, in conjunction with a PCX lens (see above). Typical applications include welding, drilling, laser ablation, and fiber coupling.

Our fly’s eye condensers arrays are available in 5 and 10mm square configurations, and are designed for flat-top and line generation. The condenser arrays are a monolithic assembly of dual-surface cylindrical microlenses, creating condensers which are completely free of adjustment. These microlenses are commonly used in applications requiring a large illuminated field with a short working distance, such as medical laser use, solar simulation, UV-curing, semiconductor instrumentation and fluorescence microscopy.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®